From research to diamond electrodes

... and beyond!

At the end of the 1990s, the scientific employees and future founders of pro aqua, Dr. Wolfgang Staber, MBA and Dr. Michael Schelch, are working at the Institute for Sustainable Waste Management and Disposal Technology at the University of Leoben. Among other things, they deal with waste water treatment processes. In the course of literature research, they come across the topic of "waste water treatment with boron-doped diamond electrodes".

Scientifically structured work is the number one prerequisite for – in our case – technical innovation.

Dr. Wolfgang Staber, MBA

Following their scientific curiosity, boron-doped diamonds are increasingly becoming a research focus for the scientists. Based on the few laboratory experiments described in scientific literature, they need to work out all the fundamentals, especially when it comes to industrial application.

An exemplary application-oriented research and innovation process is launched.

Unbeknownst to them, they are laying the foundation stone for today's company ...

2000

In the beginning

is research

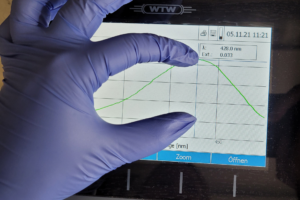

In the year 2000, there are only a few producers on the planet that manufacture boron doped diamond electrodes on a metallic basis. The electrodes of these companies are extensively tested at University of Leoben. However, none of the tested electrodes achieve service lives acceptable for an industrial application.

2002

The first patent

is filed

A spin-off is created at the UNI Leoben start-up centre with the aim of developing a completely new manufacturing process to produce and offer boron-doped diamond electrodes for industrial use. The first patent for the development of a diamond electrode is filed.

2004

The corner stone

for innovation

Dr. Wolfgang Staber, MBA and Dr. Michael Schelch establish pro aqua Diamantelektroden Produktion GmbH (pro aqua for short) together with three other scientists. Further patents for the product "diamond electrode", the process "production of diamond electrodes" and their applications follow.

2006

Rethinking

the concept

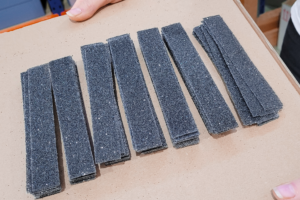

The result of almost four years of research is that the manufacturing processes developed are unable to produce a metal-based diamond electrode that is suitable for industrial application. A completely new concept is needed: The idea of the plastic-based diamond electrode is born.

2008

The pro aqua

diamond electrode

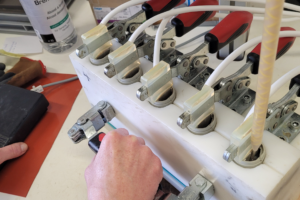

A plastic-based diamond electrode has now been available since early in the year, which will prove its worth in many different applications worldwide in the future. However, the industrial application requires that the electrodes are installed in flow cells.

2011

The team is

being expanded

Three years after the diamond electrode was ready for series production and intensive cell development, flow cells of various designs with built-in pro aqua diamond electrodes are now available. The first major customer is acquired and the first employees are hired.

2015

From electrodes

to products

Customer requests for system solutions push development. The first systems for the production of electrochemically-activated water can be offered to customers. The first B2C product, the Rain-Fresher, is also launched.

2018

A diverse

product range

Whether B2B or B2C customers – the areas of application for pro aqua products are wide-ranging and extend from the cleaning and disinfection of water, surfaces and equipment to the washing and disinfection of foodstuffs and the protection of plants and animals.

2020

Trailblazers of

a new era

The pandemic also poses new challenges for pro aqua. In SurfaceCleaner 100, it launches the next high-tech product which is now being distributed all over Europe. A system for the in-house production of an "all-in-one" disinfectant cleaner for various surfaces at the push of a button comes at exactly the right time.

2022

20 years pro aqua

In 2022, the company can look back on 20 years of history. Much has been achieved, but there were also some difficulties to overcome. The team of 13 people has generated almost €26 million at the location in Niklasdorf over the last 10 years.

2024

EN ISO 13485 and EN ISO 9001

A lot of work has gone into pro aqua's new, integrated quality management system. This has paid off: the company meets the high standard for the production of medical products in accordance with EN ISO 13485, as well as the criteria of EN ISO 9001, and is able to prove this with both certificates since 2024.